Developed in Japan – The 5S Methodology is a philosophy that advocates using specific steps to organize the workplace as well as working practices. Its goals are to improve efficiency and eliminate waste.

Developed in Japan – The 5S Methodology is a philosophy that advocates using specific steps to organize the workplace as well as working practices. Its goals are to improve efficiency and eliminate waste.

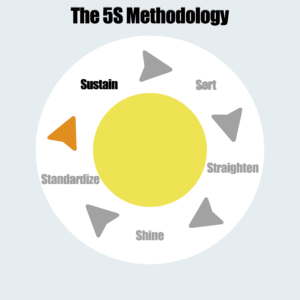

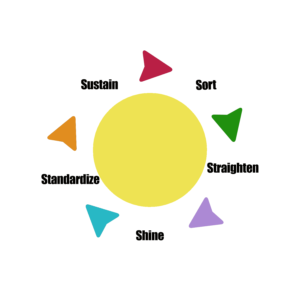

The five steps/S’s to improve efficiency are:

Sort (Seiri), Straighten or Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke).

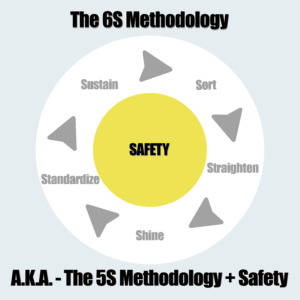

When you add Safety – the sixth S – you have The 6S Methodology.

In essence, it’s applying all your company’s safety guidelines into the execution of all five S’s.